Insulation materials: industry outline

The insulation industry plays a significant role in overcoming challenges related to energy consumption and sustainable construction. Effective insulation materials can contribute significantly to energy savings and CO2 emissions.

Various types of insulation materials are produced, such as glass wool, rock wool, polystyrene (EPS and XPS), polyurethane foam (PUR and PIR), wood fiber, cellular glass and also natural insulation materials such as hemp, sheep's wool and cellulose. The increased demand for sustainable construction has led to the use of more insulation materials.

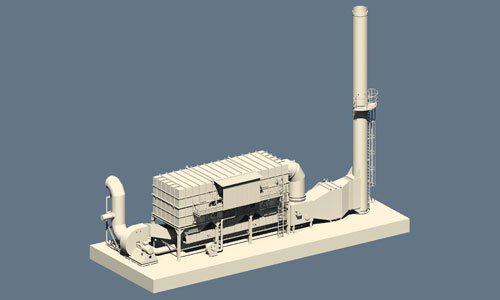

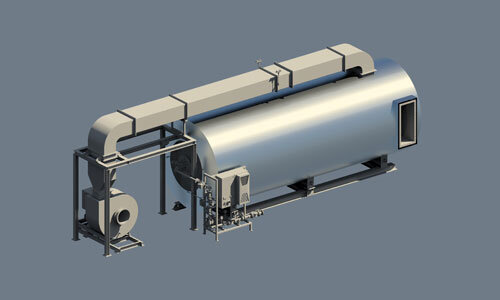

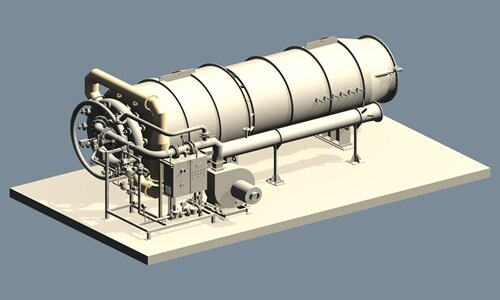

Insulation materials such as rock wool is produced by fusing stone, limestone and recycled bricks with other raw materials at approx. 1,500 °C. Binding and impregnating agents are added. The industry requires high-performance exhaust air purification systems in order to clean the exhaust air produced economically.