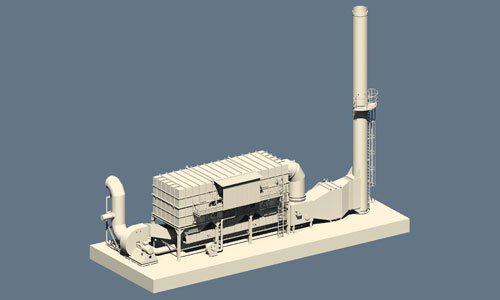

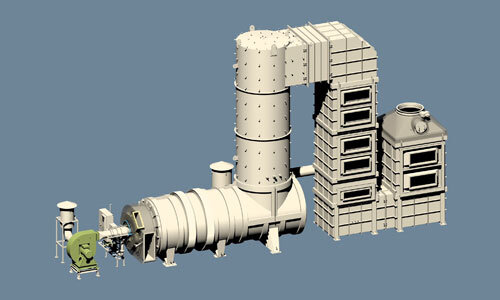

compact TNV

Thermal afterburning - recuperative compact system

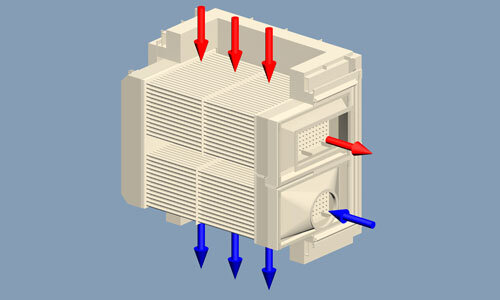

Efficient energy utilization is ensured by the integrated tube bundle heat exchangers. The compact design enables flexible integration into the production process and efficient energy recovery through recirculation into the process. The patented secondary air burner uses the processed air as combustion air, thereby significantly reducing energy consumption. Our basket burner is a versatile burner system that can be operated with natural gas, oil, liquid gas and other fuel or process gases. Conversion to other fuels is possible without any problems.