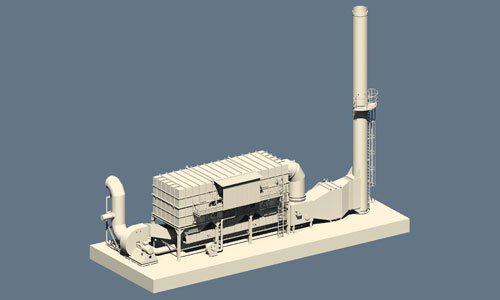

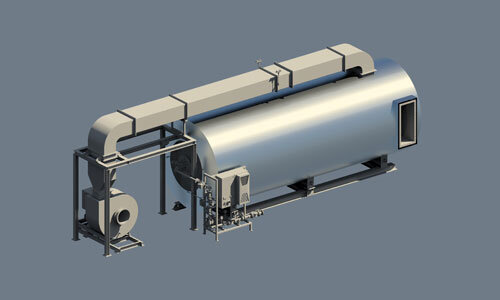

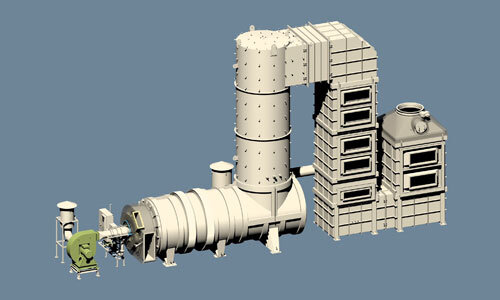

Combustion chamber

Combustion chamber

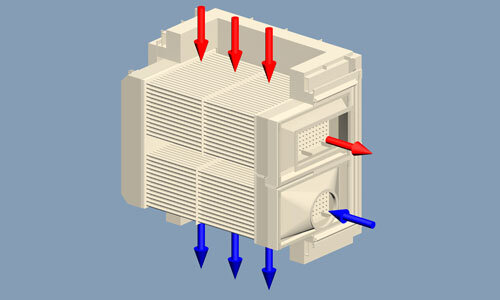

Each combustion chamber is customized specifically for your incineration process. It is the optimum solution for complex exhaust air flows and difficult installation conditions. We develop a tailor-made solution for optimum process integration and maximum energy efficiency. Performance and design can be individually adapted to your requirements. The design of the internal insulation or brick lining can be used appropriately for the application to protect the reactor for high temperature impact or corrosion.