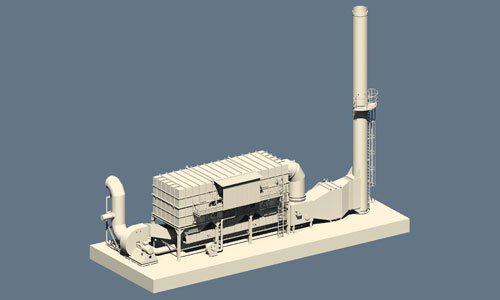

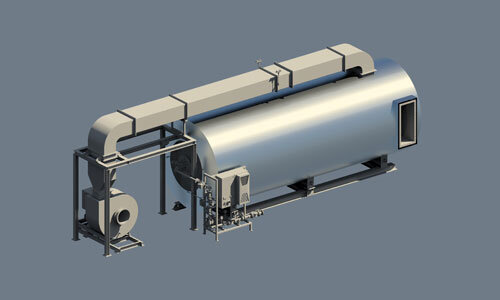

Engineering Made in Germany

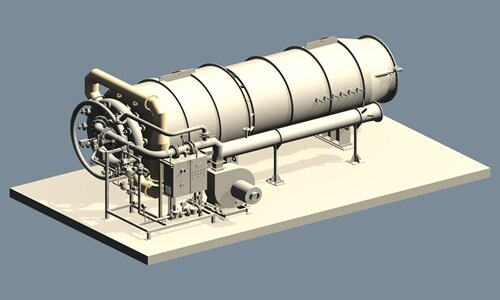

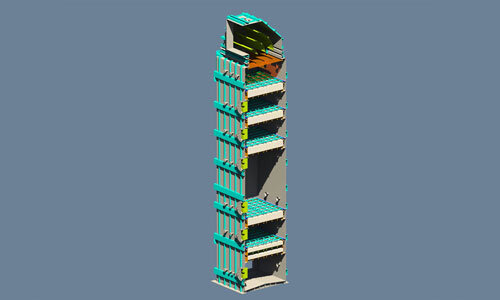

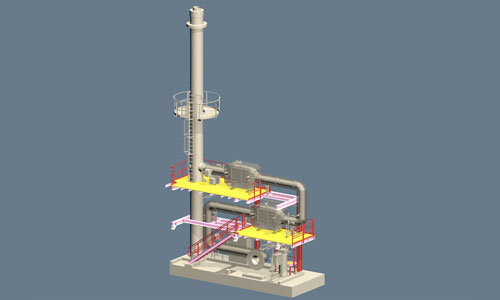

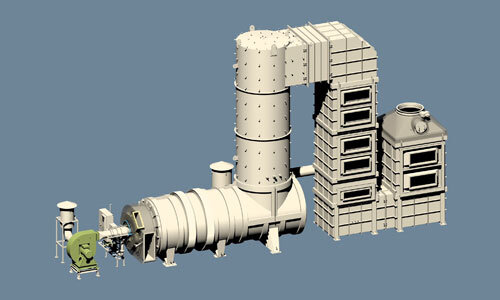

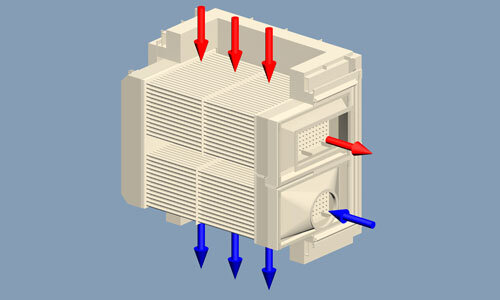

Exhaust air & waste gas purification

Envirotec is your partner for industrial exhaust air and waste gas purification. From the initial planning study to the commissioning of your system, we offer innovative solutions. Our range of services is rounded off by predictive and preventive maintenance as well as a comprehensive after-sales service. Experienced project management, comprehensive know-how and first-class service guarantee our customers sustainability, a significant reduction in CO2 emissions and measurable cost savings.

Envirotec is a family business standing for technological progress and quality since 1980.